OUR PROCESS

EMPOWERING YOUR VISION

FROM CONCEPT TO MARKET

At Acrivia, we merge creativity with precision engineering and manufacturing prowess to turn your ideas into market-leading products. Our integrated approach ensures a seamless transition from initial design through to mass production, all under one roof.

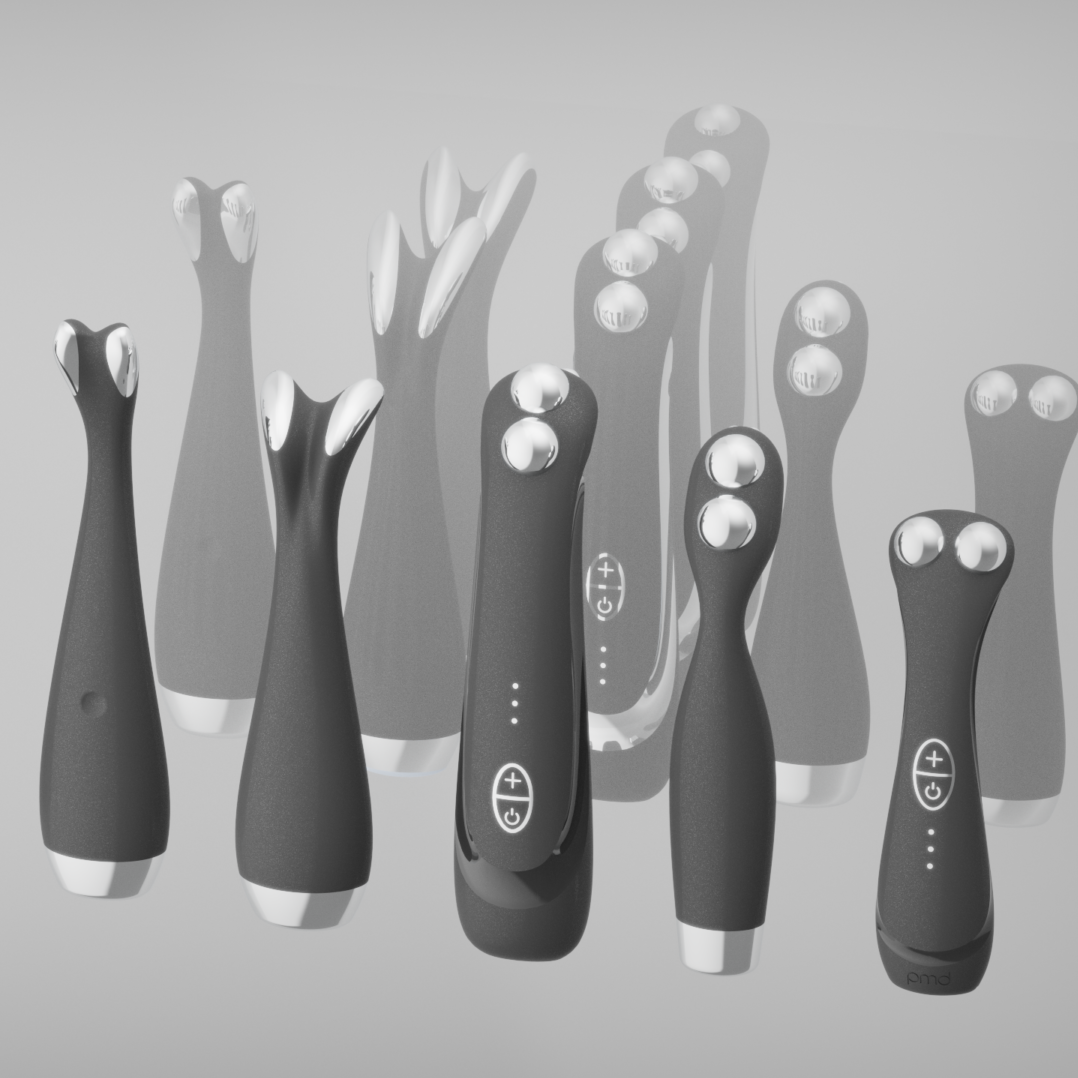

DESIGN

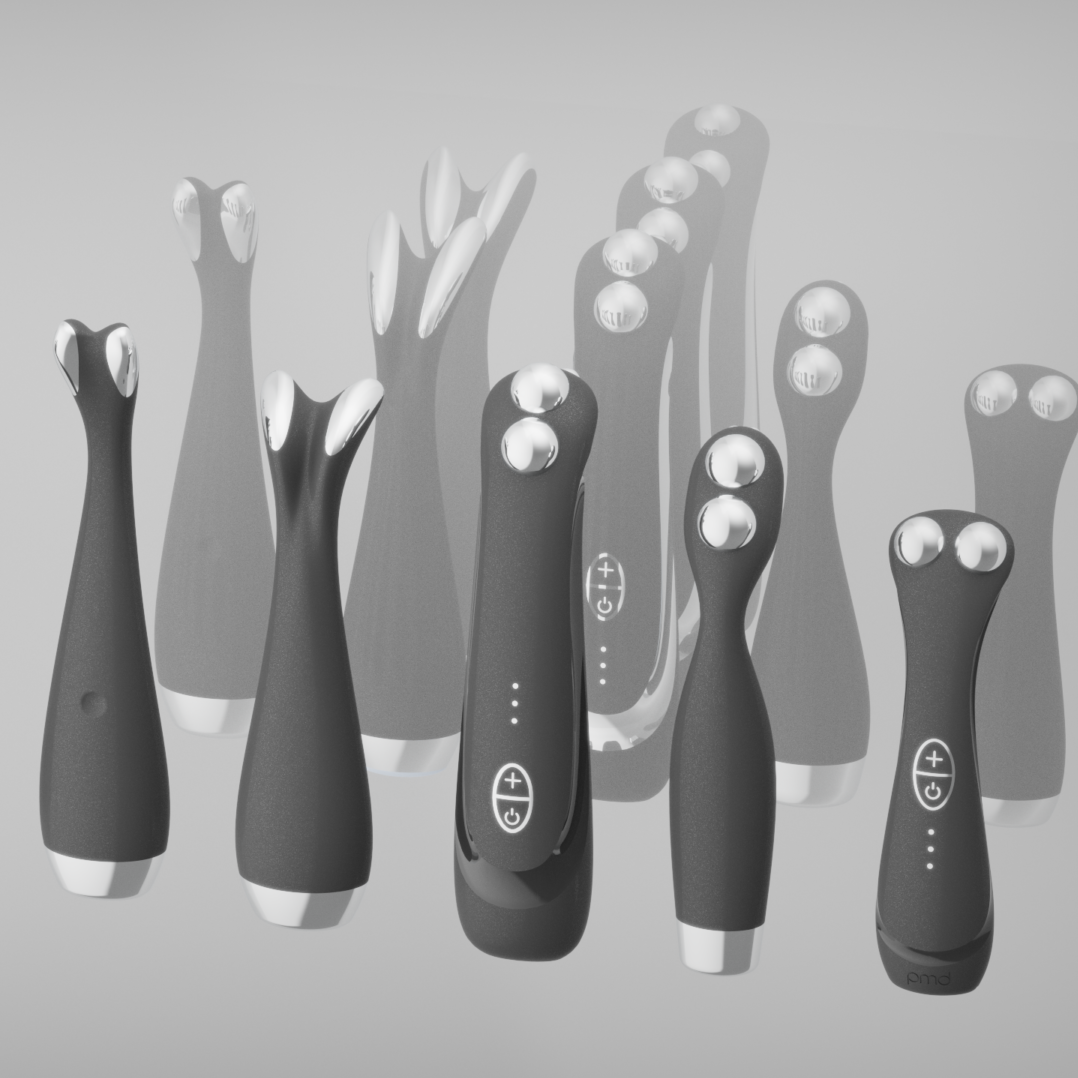

Exceptional product design merges form and function setting the foundation for market success, distinguishing your offering with innovation that directly addresses consumer needs. Ultimately, it drives customer loyalty and brand differentiation, ensuring your product stands out in a crowded marketplace. Our team of designers work with you to create the exact desired look and feel for your product, ensuring these aspects are considered from start to finish of the Acrivia formula.

01

IDEATE

Brainstorming, researching, and generating innovative ideas to solve specific problems or meet market needs. Where the vision for the product begins to take shape through sketches, storyboards, or digital concepts.

DEVELOP

Ideas from the ideation stage are transformed into tangible designs. Prototyping, testing, and iterative refinements are key activities to validate the design and ensure it meets all requirements and specifications.

FINALIZE

Preparing the product for engineering and DFM through industrial design finalization. Iterating through multiple design concepts to determine best design to continue development.

IDEATE

Brainstorming, researching, and generating innovative ideas to solve specific problems or meet market needs. Where the vision for the product begins to take shape through sketches, storyboards, or digital concepts.

DEVELOP

Ideas from the ideation stage are transformed into tangible designs. Prototyping, testing, and iterative refinements are key activities to validate the design and ensure it meets all requirements and specifications.

FINALIZE

Preparing the product for engineering and DFM through industrial design finalization. Iterating through multiple design concepts to determine best design to continue development.

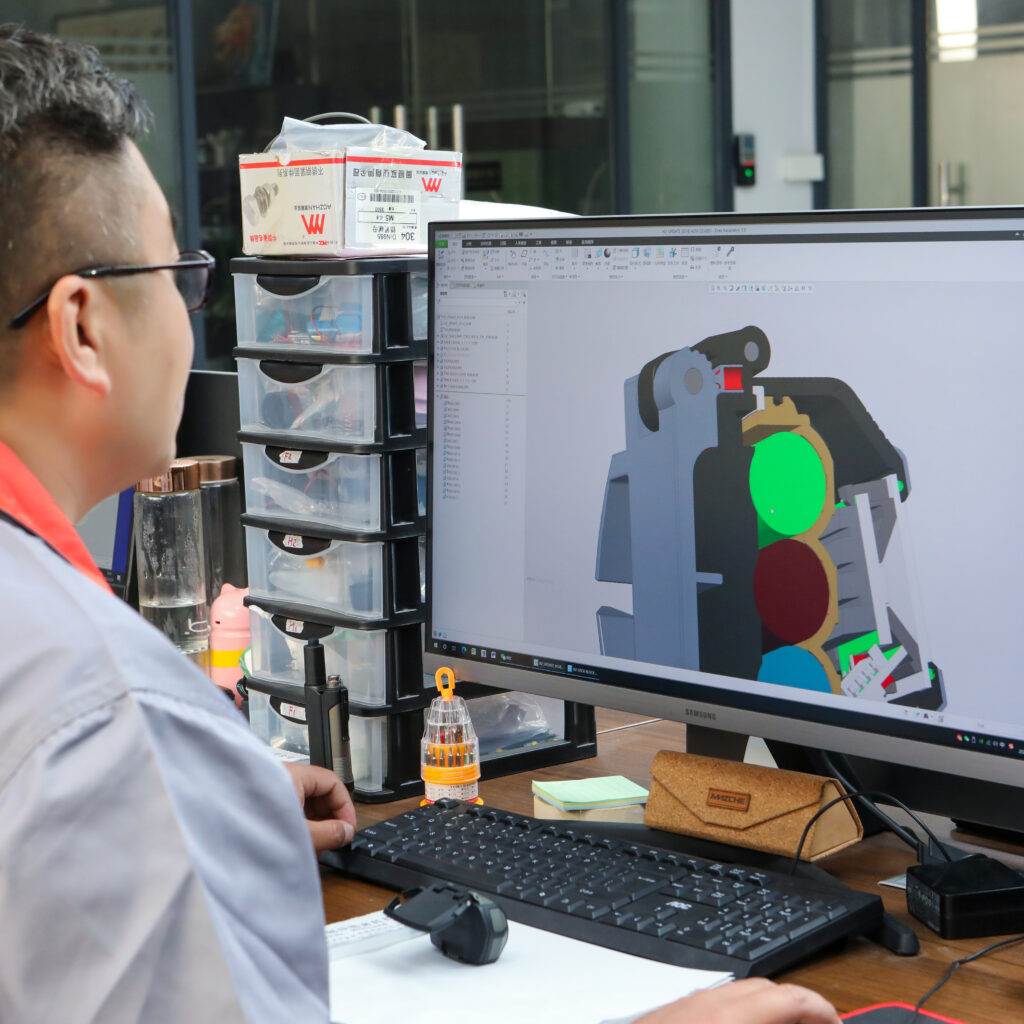

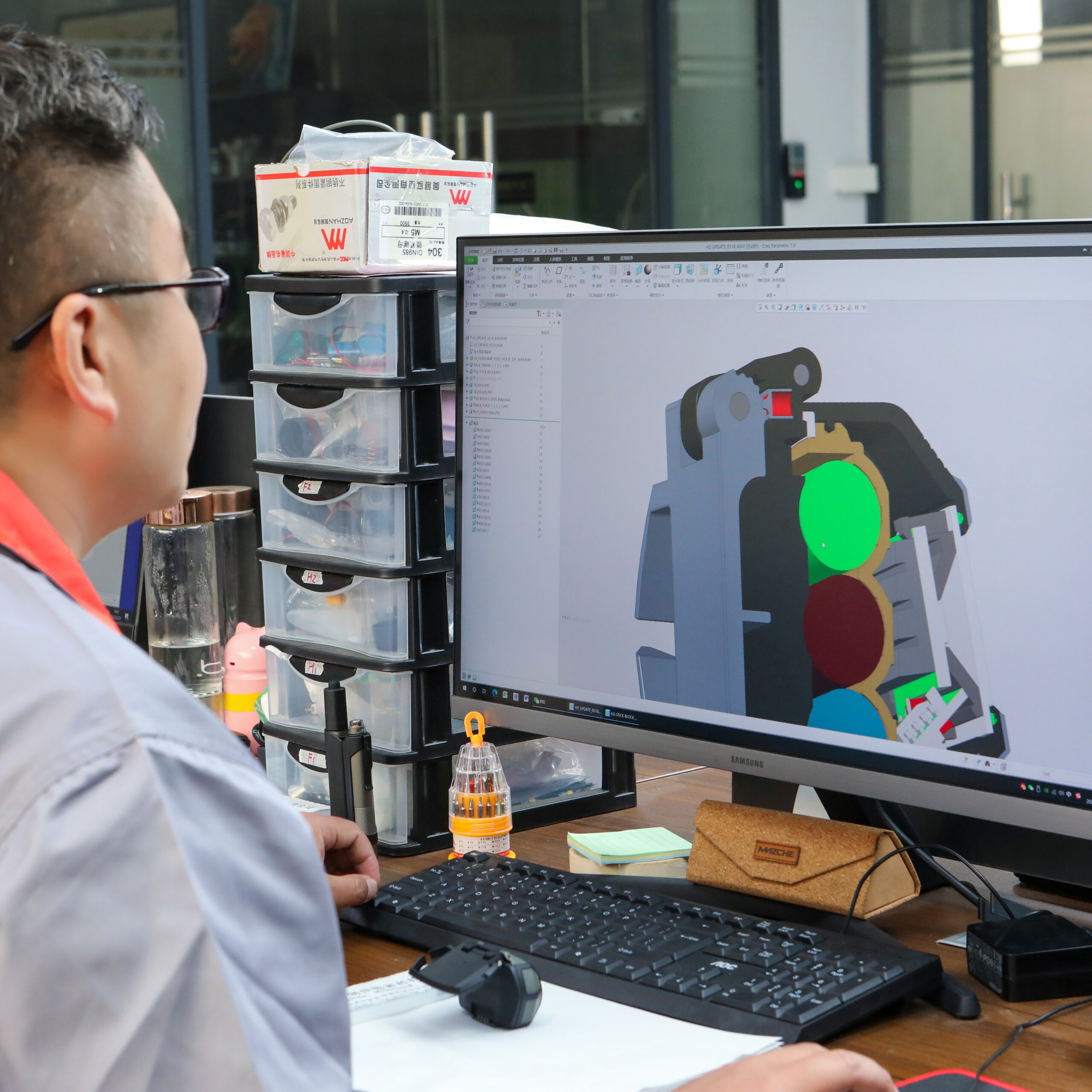

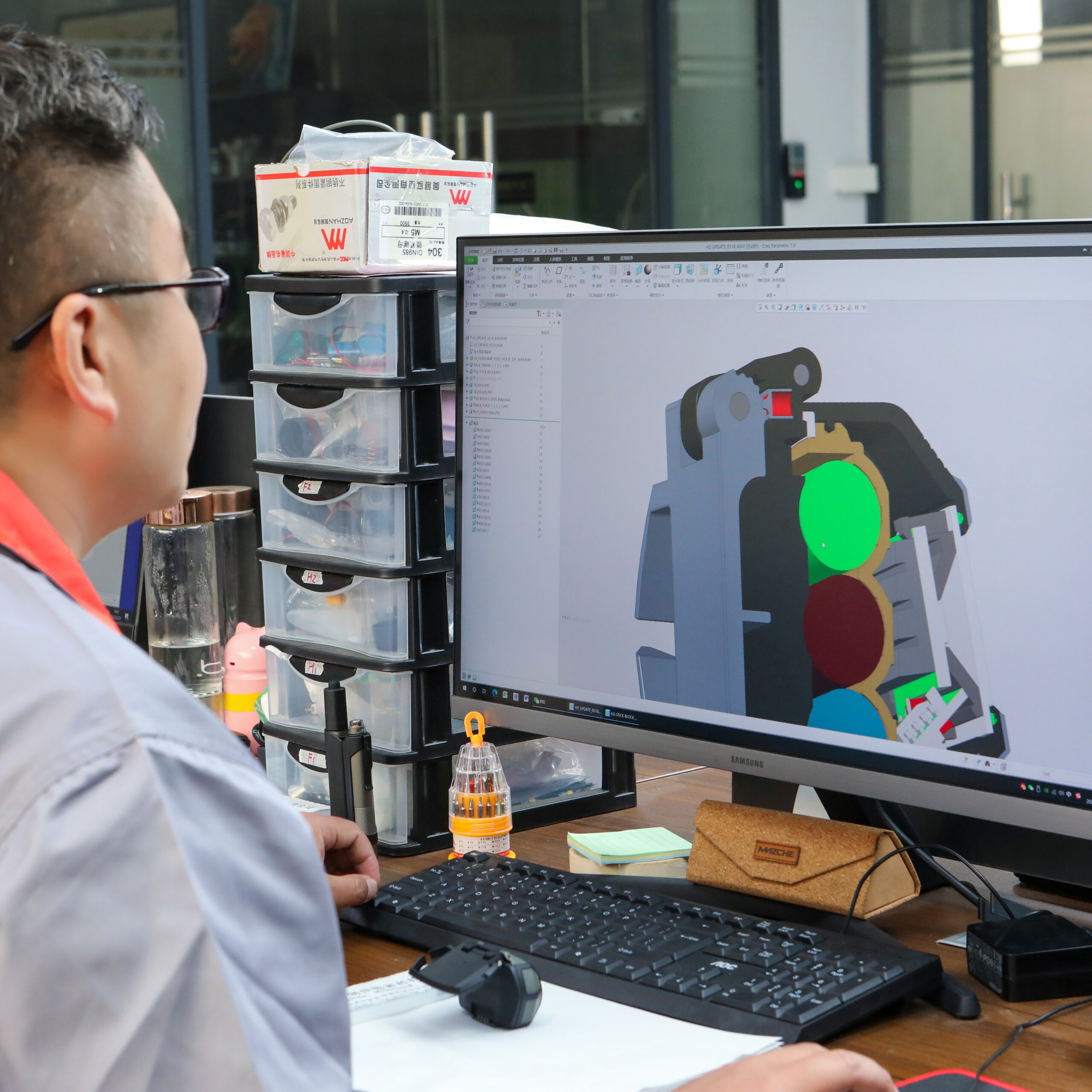

ENGINEER

Acrivia engineering transforms creative concepts into practical, functional products, ensuring they are safe, reliable, and manufacturable at scale. It bridges the gap between design aesthetics and physical feasibility, optimizing for performance, cost-efficiency, and user satisfaction. Through rigorous testing and refinement, engineering also ensures that products meet both market expectations and regulatory standards, crucial for long-term success.

02

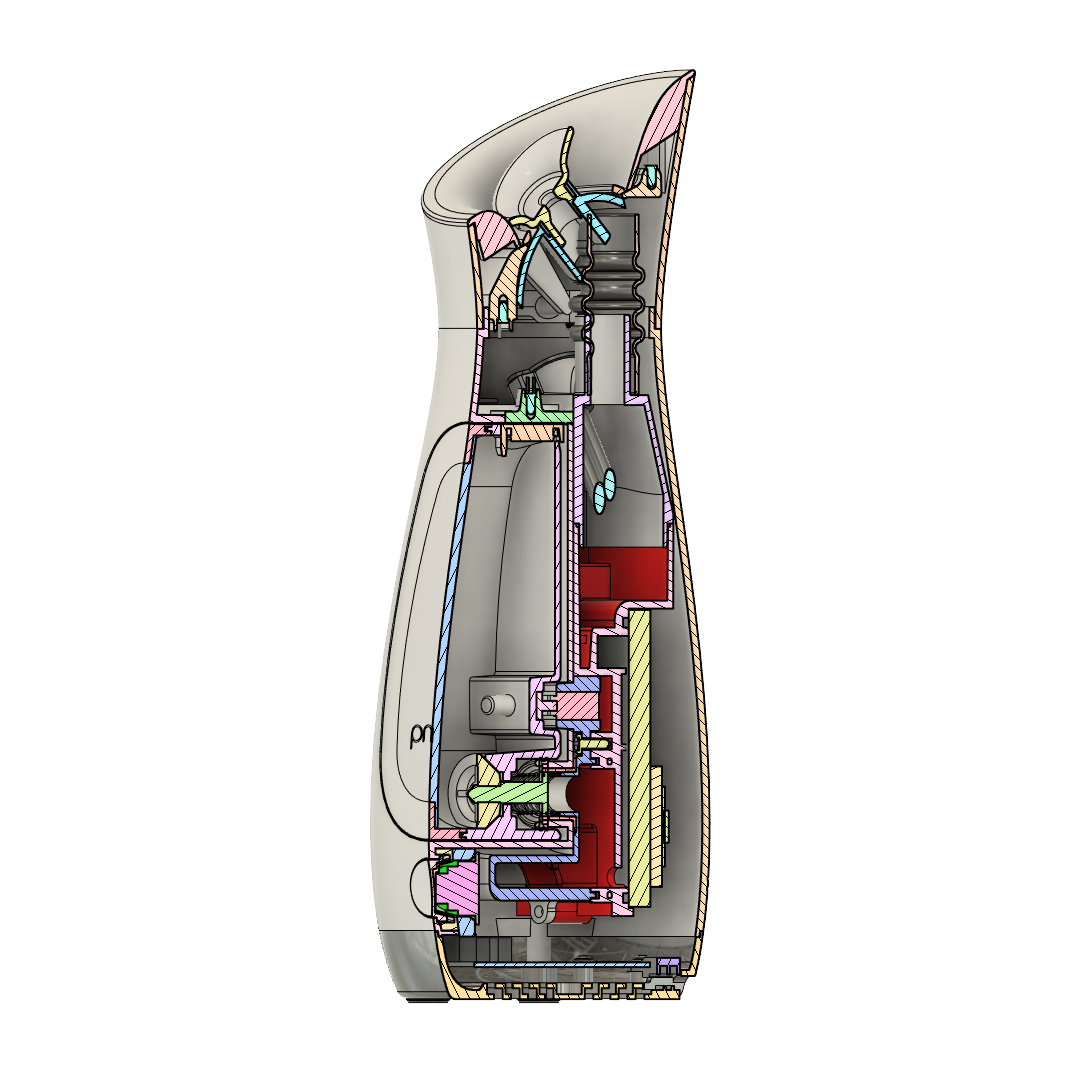

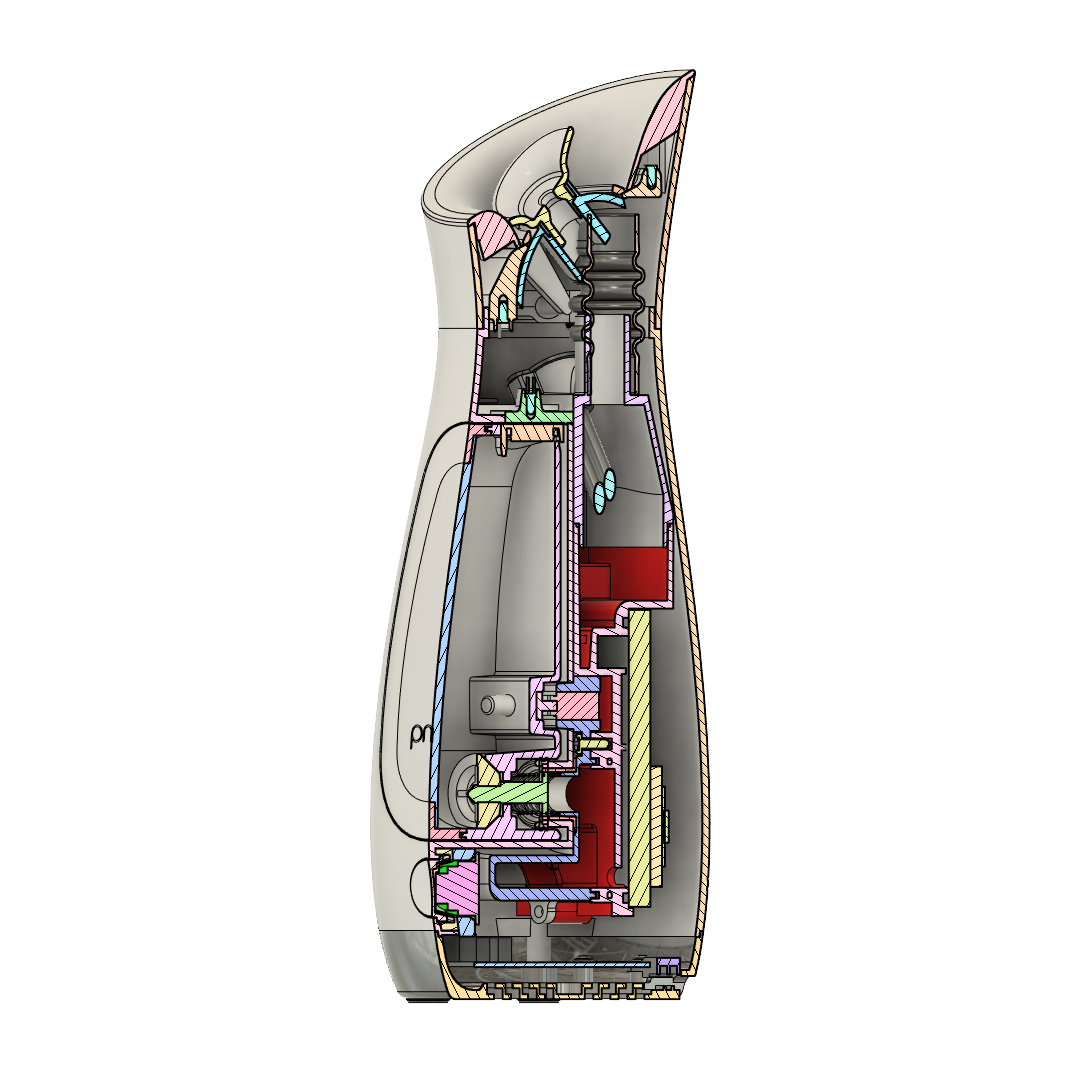

ENGINEERING VALIDATION

Translating industrial designs into detailed engineered designs, incorporating technical specifications, materials selection, and the integration of necessary technologies to meet functional requirements.

DESIGN VALIDATION

Environmental and regulatory testing and compliance and creating prototypes to test the design, functionality, and performance of the product against predefined criteria, allowing for adjustments and refinements based on real-world feedback.

DFM & PRODUCT VALIDATION

Design for Manufacturability (DFM) is Acrivia’s product design approach that simplifies the manufacturing process to reduce production costs and lead times. It involves optimizing the design of a product for ease of fabrication, assembly, and testing, ensuring efficiency and cost-effectiveness in mass production.

ENGINEERING VALIDATION

Translating industrial designs into detailed engineered designs, incorporating technical specifications, materials selection, and the integration of necessary technologies to meet functional requirements.

DESIGN VALIDATION

Environmental and regulatory testing and compliance and creating prototypes to test the design, functionality, and performance of the product against predefined criteria, allowing for adjustments and refinements based on real-world feedback.

DFM & PRODUCT VALIDATION

Design for Manufacturability (DFM) is Acrivia’s product design approach that simplifies the manufacturing process to reduce production costs and lead times. It involves optimizing the design of a product for ease of fabrication, assembly, and testing, ensuring efficiency and cost-effectiveness in mass production.

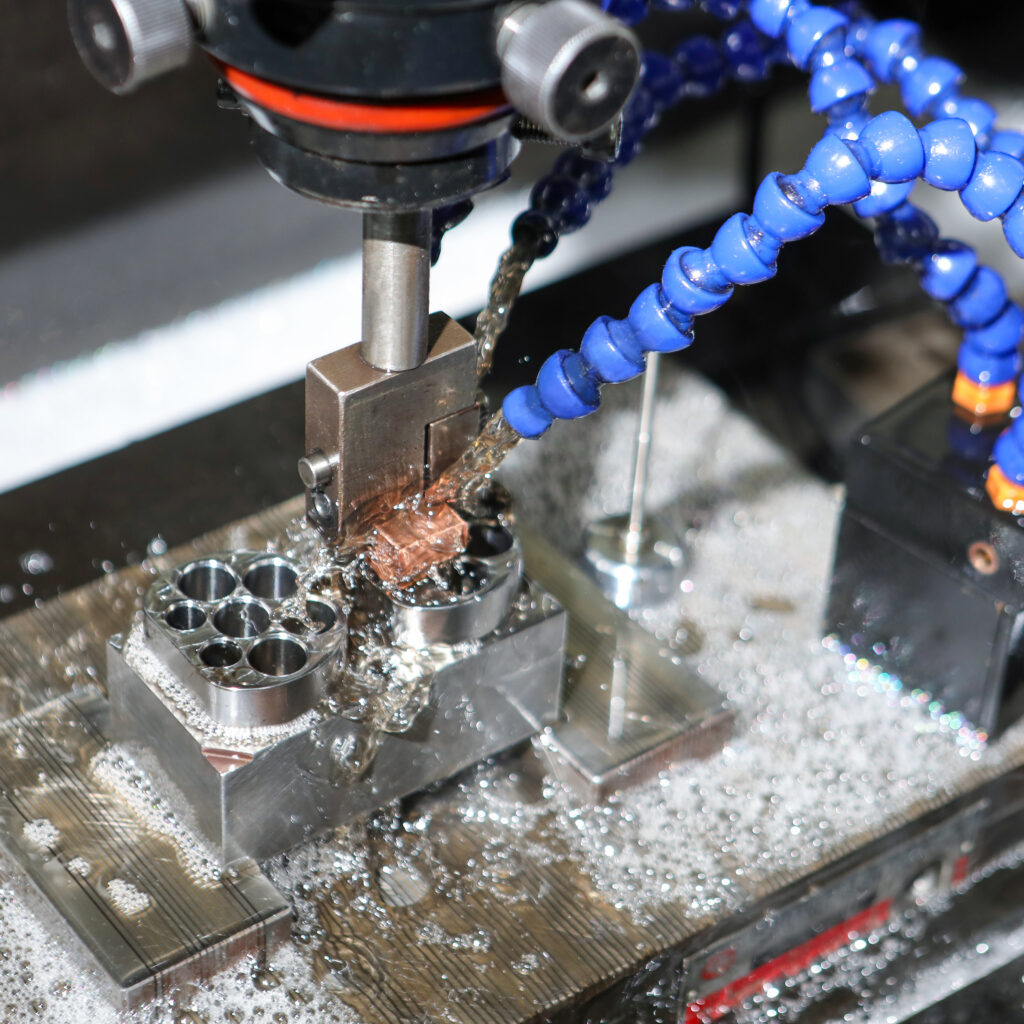

MANUFACTURE

Acrivia’s injection molding facility, equipped with in-house tooling and fabrication capabilities, sets the standard for precision, customization, and speed in bringing your products from concept to reality. By integrating advanced molding techniques with comprehensive assembly services, we offer a seamless, cost-effective solution for high-quality production at any scale. Choose us for a partnership that combines technical excellence with meticulous attention to detail, ensuring your project’s success from the ground up.

03

QUALITY CONTROL

Acrivia’s ISO 13485 and 9001 certified facility ensures the highest standards in quality management and product safety for medical and consumer devices, offering clients unparalleled reliability, compliance, and efficiency in bringing products to market.

VERTICALLY INTEGRATED

In-house injection molding, tooling fabrication, jig and fixturing, assembly and kitting, final packout and shipment preparation ensure speed, control, and repeatability crucial to an ever competitive marketplace.

SPECIALIST KNOWLEDGE

Our specialized experience is vital for optimizing production processes, ensuring product quality, and reducing costs by expertly navigating the complexities of material behavior, mold design, machine settings, and other facets in production that propel our partners ahead.

FULL SERVICE LIST

QUALITY CONTROL

Acrivia’s ISO 13485 and 9001 certified facility ensures the highest standards in quality management and product safety for medical and consumer devices, offering clients unparalleled reliability, compliance, and efficiency in bringing products to market.

VERTICALLY INTEGRATED

In-house injection molding, tooling fabrication, jig and fixturing, assembly and kitting, final packout and shipment preparation ensure speed, control, and repeatability crucial to an ever competitive marketplace.

SPECIALIST KNOWLEDGE

Our specialized experience is vital for optimizing production processes, ensuring product quality, and reducing costs by expertly navigating the complexities of material behavior, mold design, machine settings, and other facets in production that propel our partners ahead.

Market Research

Business Strategy

Concept Iterations

Form Generations

CAD Refinement

Renderings

Product Computer Animation

Low and High Fidelity Prototypes

Material Specification

Design for Manufacturing

Specification Creation

In-house Mechanical and

Electrical Engineering Team

FEA and Thermal Analysis

Compliance and Certification

(UL, CE, ETL, FCC etc…)

ISO 9001:2015 Facility

Sourcing and Logistic

App and Firmware Development

Functional Prototype

Pre-Production Runs

In-House Injection Molding

In-House Machining

In-House Assembly and QC

Design Cost Optimization

Mold Optimization

PCB Schematic and

Component Selection

Market Research, Business Strategy, Concept Iterations, Form Generations, CAD Refinement, Renderings, Product Computer Animation, Low and High Fidelity Prototypes, Material Specification

Design for Manufacturing, Specification Creation, In-house Mechanical and Electrical Engineering Team, FEA and Thermal Analysis, Compliance and Certification (UL, CE, ETL, FCC etc…), ISO 9001:2015 Facility, Sourcing and Logistic, App and Firmware Development

Functional Prototype, Pre-Production Runs, In-House Injection Molding, In-House Machining, In-House Assembly and QC, Design Cost Optimization, Mold Optimization, PCB Schematic and Component Selection

TEXAS USA

2020 E Randol Mill.

Arlington,

TX 76011

CHINA

2/F, building 3, Creative Factory,

No.166, Shima Jianshe Rd, Tangxia,

Dongguan, Guangdong, 523731

HONG KONG

Suite 1019, 10/F.,

Chinachem Golden Plaza,

77 Mody Road, Tsimshatsui, Kowloon

SPAIN

C/ de Bailèn, 11, L’Eixample,

BCN 08010

TEXAS USA

2020 E Randol Mill.

Arlington,

TX 76011

CHINA

2/F, building 3, Creative Factory,

No.166, Shima Jianshe Rd, Tangxia,

Dongguan, Guangdong, 523731

HONG KONG

Suite 1019, 10/F.,

Chinachem Golden Plaza,

77 Mody Road, Tsimshatsui, Kowloon

SPAIN

C/ de Bailèn, 11, L’Eixample,

Urquinaona,

BCN 08010